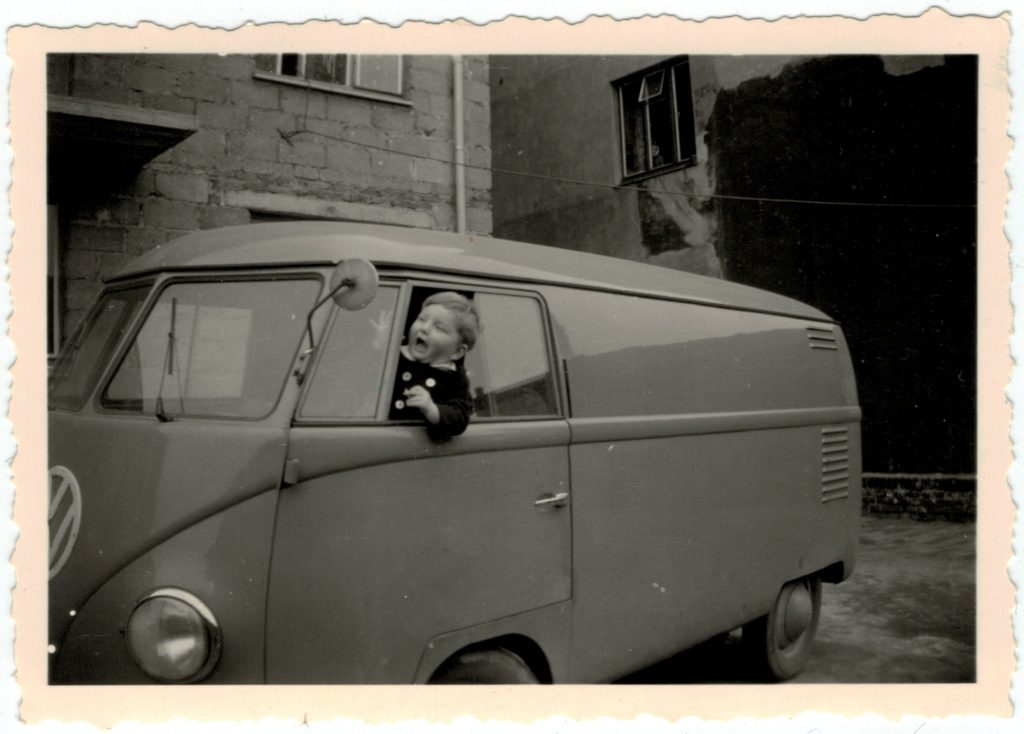

This brave young guy here, my dear VW-friends, doesn´t need any brakes for the ride in his ´51 panel……

…..but I need some in my ´51, cause I am way less brave!

So, I better finalize my job regarding the master cylinder of the Samba! Do you remember the post about the master cylinder? (in case you missed it please scroll down some posts).

Since the original master was way too far gone even in my eyes, we decided to go for a new master, but anything else, the screws, the reservoir and the brake light switch we want to be old original material. That´s what this little update is all about.

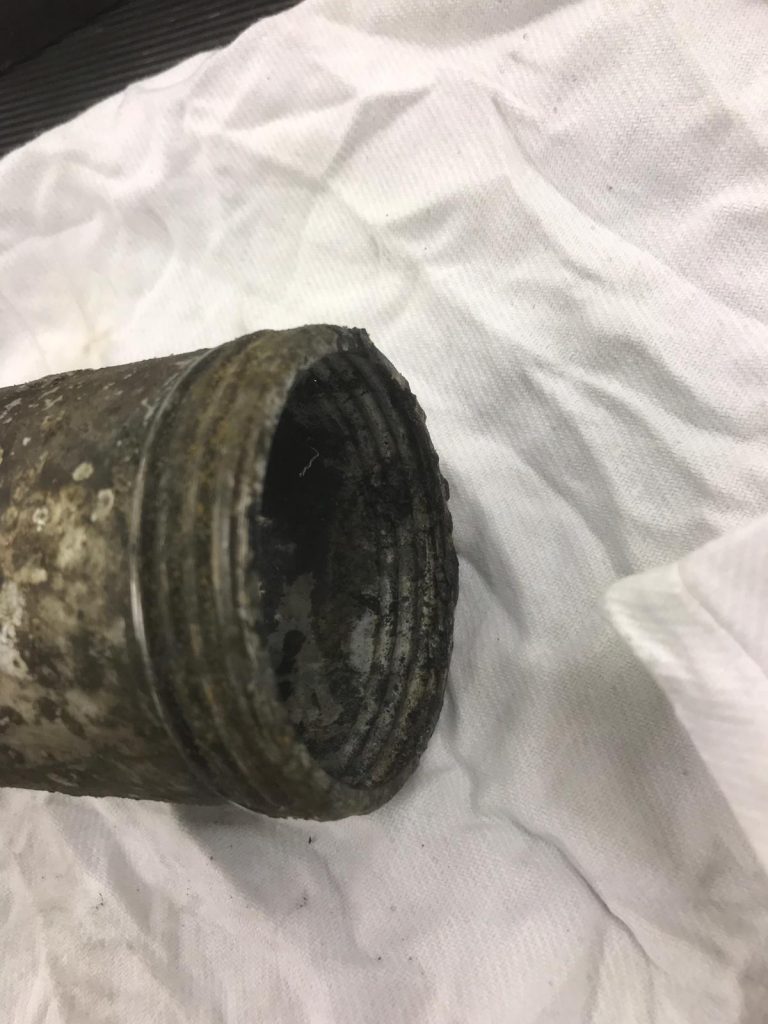

When the Samba was found the original very first brake fluid container was still in place.

That´s another proof the Bus didn´t have a very long first life, neither did it run a high mileage. How many pre ´54 VWs you have seen still with their aluminum containers mounted? Hardly any I would guess or if you have seen one the car was taken from the roads very early. The later plastic container was so much better (plus cheap and easy to replace), because you could check the level of the brake fluid without removing cap! But the Samba still had its first unit, but as with so many other original parts found with the Samba it was in very, very poor condition. Just have a look and see the problem I was faced with:

You know me by now. This hole in the container isn´t a reason the replace an original piece, it´s just a challenge! On the other hand it is still a safety item and safety is no subject to joke with just due my originality-freak-show. But I had an idea….

First of all, let´s remove the stuck cap without destroying the soft aluminum.

So, here is my compromise between originality up to the limit and safety: a custom made inner container to slip into the original rotten surface. Cool, isn´t it?

Now, let´s grab our original fixing screw with the new sieve and a new copper sealing ring to fix the container on the master.

Now let´s have a look on the brake light switch which was with the old rotten, but original master:

This switch didn´t look to me to be original! As far as I know the early brake light switches always had a bar between the two poles, minimum as long as the switches came from ATE. Did VW equipped any ´51 car with something else but masters made by ATE? I doubt it.

Here are two ATE switches right beside the rotten switch of the Samba. The used ATE switch came from a very untouched ´51 Bus and the new one is a NOS item made in 1953 as the date stamp states.

As the difference between the ´51 made used ATE switch and the NOS ´53 made ATE switch is hard to see at all (it´s just the high of the bar between the poles) I decided to mount the NOS switch to the master. The rotten one isn´t original anyway, so there is no need to invest a lot of time to restore it.

Ha! I can´t wait to see TÜV (=MOT or DMV) inspector´s shocked face when he is going to discover this master! But I am sure the Samba will pass the test after a second close of the inspector. I don´t expect him to understand why we made such an effort just to use the rotten container again, but I would appreciate if you, the real VW-nerds, agree that this compromise between originality and safety is the right way. What do you think? You are welcome to leave a comment.

Have a nice weekend!

Florian

Hits: 0

9 thoughts on “Caution! This post may contain an offensive…. container!”

I know that this is an older blog post, and I only have a very minor annotation to make, but seeing that you take even seemingly minor details very serious, I would like to state that the figures ’31’ and ’53’ in the embossing of the NOS brake light switch are no indications of production dates.

In the book ‘Kunststoff-Ratgeber – Tabellen und Gestaltungsregeln für die Verarbeitung von Kunststoffen, insbesondere Kunstharzpreßmassen’ by Kurt Brandenburger, Verlag W. Girardet, Essen, 2nd edition 1950, the principal components of the ‘Typenzeichen’ are explained on page 38.

Let me start with the remark that the outlines of the ‘Typenzeichen’ are formed by the letters MPD, which stood for ‘Materialprüfungsanstalt Dahlem’, the precursor of the Bundesanstalt für Materialforschung und -prüfung in Berlin-Dahlem.

So if you look at the ‚Typenzeichen‘ in the way the letters are oriented, the upper number ‚53‘ indicates the producer of the Preßmasse piece, running number 53 on the (then) official list of manufacturers: Ernst Backhaus & Co. in Kierspe-Bahnhof (Westphalia).

And on page 35 of the aforementioned book, in a ‘Übersicht über Preßstoffe – Typenliste’, you’ll find that the ’31’ indicates a warm pressed ‘Preßstoff’ made from ‘Phenolharz mit Holzmehl’.

Type 31 was the most common type of phenolic moulding material back then, widely known by its trade mark name Bakelite.

The denomination of this type of Pressmasse had been changed just a few years earlier; up to 1946 (I think, but don’t quote me on this) it was called ‘Schnellpreßmasse Typ S’, so you would have found an ‘S’ in place of the ’31’ on earlier Pressmasse products.

In addition, a production date post 1945 is also indicated by the small dot in the lower right field of the embossing.

To round things up, let me explain the figure ‚1‘ to the left of the ‚31‘ – it indicates a specific quality of the Preßmasse, namely moderate shrinkage. So the precise material specification would have read ‚31,1‘ back then.

I hope this answers any questions on the ‚Typenzeichen‘ that you may or may not have ever had … 😉

Great work as always Floiran, a very clever fix for the brake fluid reservoir.

Keep the updates coming. Myself and my colleagues hear at VW Heritage always look forward to them with great anticipation.

I think your master cylinder is spot on with the theme of your project! Thank you again for your continual updates. And I just love your old photos of VWs!!! Maybe sometime you can post all of your photo collections on line.

Like always thank you thank you!

I’m very intrigued and interested in your restoration- very good

I would have made the inner reservoir clear if possible and pierced the outer original with a narrow vertical slot to indicate max and min levels

That way you show off what you have done a bit more and it’s practical as well

I can’t really fault your work though…….

That is brilliant thinking ! I guess you made the new container on a lathe from Polyamid or brake fluid proof vinyl/ABS stock? Are you going to make that available from your shop, please ?

there’s also a rotten out bottom on the m/c reservoir on my 55 that needs repaired as well. the aluminium container is so much prettier than the plastic thing.

I didn´t expect there is somebody else who would like to go the same way… But sure I can produce some more of these for the shop.

I would definitely be interested, since this is also a safety aspect. and the aluminium can is simply a beautiful part to safe. If you are making it available at a reasonable price, would you mind sending me an email please?

mit schönen Grüßen aus österreich

Günter

Let me try. The one we have made was pretty expensive when calculating the time we had to invest. I will calculate a small series of 30 pieces and announce the price here. 🙂

sounds great! 🙂